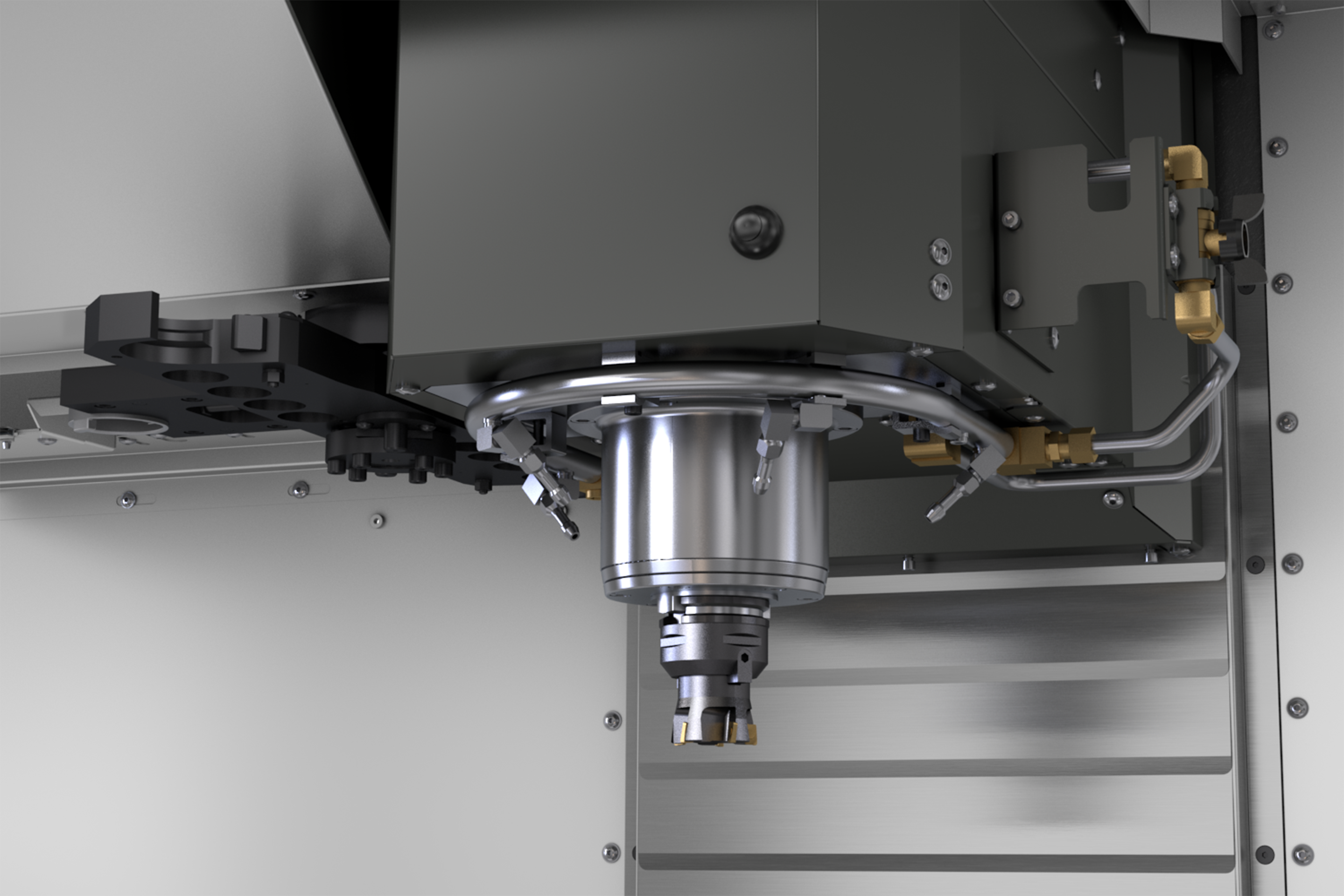

| SPINDLES | 8100-rpm Spindle |

|---|---|

| TOOL CHANGERS | 20-Pocket Carousel Tool Changer |

| CHIP & COOLANT MANAGEMENT | Window Air Blast 55-Gallon Coolant Tank Variable Flow Coolant |

| THE HAAS CONTROL | Control Touch Screen Media Display M-Code; M130 HaasConnect: Remote monitoring Early Power-Failure Detection Module Ethernet Interface WiFi Connection for the Haas Control Safe Run HaasDrop Rigid Tapping Standard Program Memory, 1 GB Internal High-Voltage Isolated Transformer |

Not all options are compatible with each other. Some options may require the purchase of additional options, or may include additional options at no charge. Please use our Build-&-Price tool to determine option compatibility, and configure your machine.

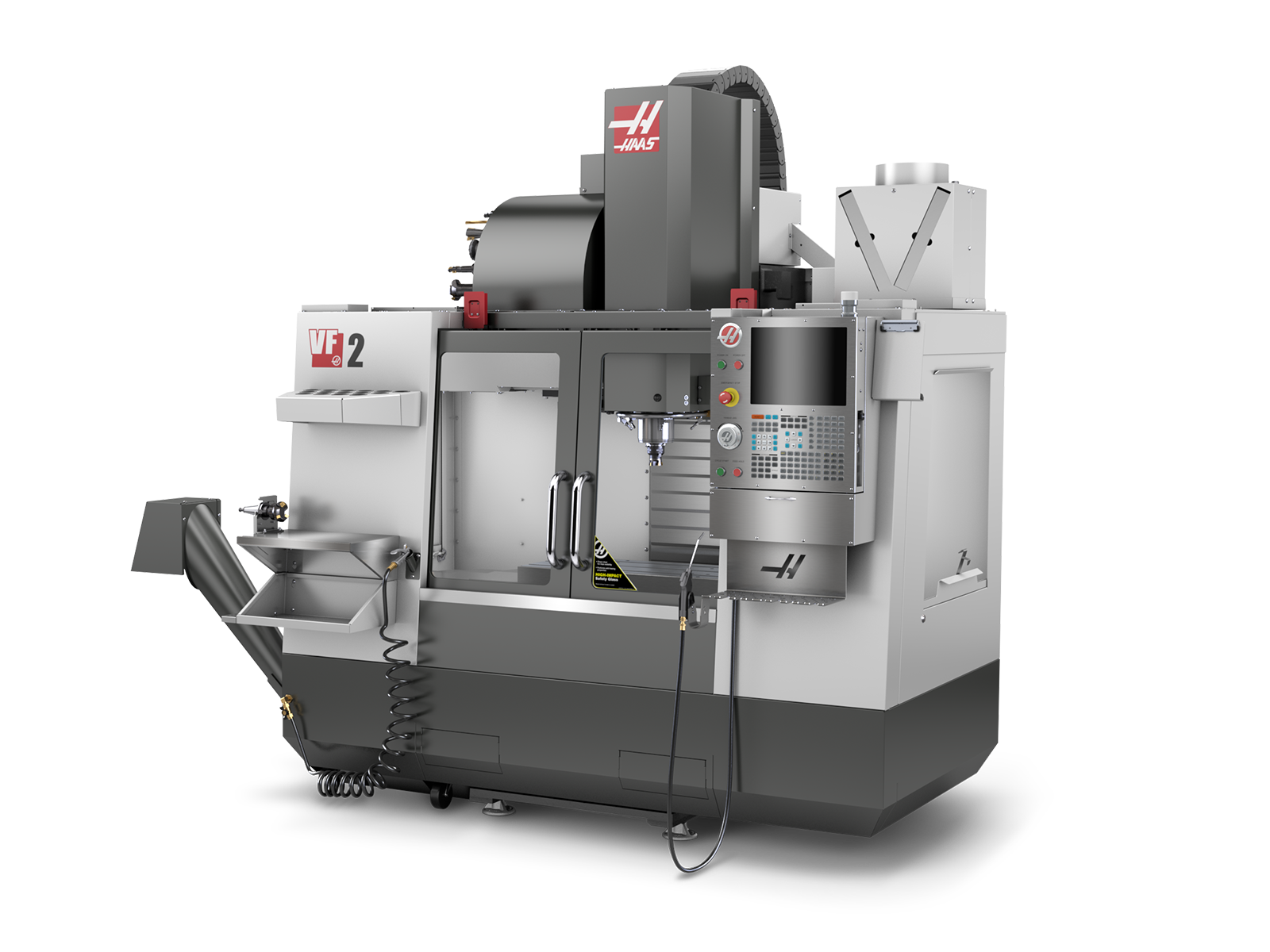

Haas offers a wide range of VF Series CNC models to match any size and production requirement. Regardless of your needs, there’s a VF just right to meet the demands of your machine shop. Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needs. All Haas machines are designed and built in Oxnard, California, USA.

The VF-2 is our most popular model, and the workhorse of any shop.

| TRAVELS | S.A.E | METRIC |

|---|---|---|

| X Axis | 30.0 in | 762 mm |

| Y Axis | 16.0 in | 406 mm |

| Z Axis | 20.0 in | 508 mm |

| Spindle Nose to Table (~ max) | 24.0 in | 610 mm |

| Spindle Nose to Table (~ min) | 4.0 in | 102 mm |

| SPINDLE | S.A.E | METRIC |

|---|---|---|

| Max Rating | 30.0 hp | 22.4 kW |

| Max Speed | 8100 rpm | 8100 rpm |

| Max Torque | 90.0 ft-lbf @ 2000 rpm | 122.0 Nm @ 2000 rpm |

| Max Torque w/opt Gearbox | 250 ft-lbf @ 450 rpm | 339 Nm @ 450 rpm |

| Drive System | Inline Direct-Drive | Inline Direct-Drive |

| Taper | CT or BT 40 | CT or BT 40 |

| Bearing Lubrication | Air / Oil Injection | Air / Oil Injection |

| Cooling | Liquid Cooled | Liquid Cooled |

| TABLE | S.A.E | METRIC |

|---|---|---|

| Length | 36.0 in | 914 mm |

| Width | 14.0 in | 356 mm |

| T-Slot Width | 0.630 in | 16 mm |

| T-Slot Center Distance | 4.92 in | 125 mm |

| Number of Std T-Slots | 3 | 3 |

| Max Weight on Table (evenly distributed) | 3000 lb | 1361 kg |

| FEEDRATES | S.A.E | METRIC |

|---|---|---|

| Max Cutting | 650 ipm | 16.5 m/min |

| Rapids on X | 1000 ipm | 25.4 m/min |

| Rapids on Y | 1000 ipm | 25.4 m/min |

| Rapids on Z | 1000 ipm | 25.4 m/min |

| AXIS MOTORS | S.A.E | METRIC |

|---|---|---|

| Max Thrust X | 2550 lbf | 11343 N |

| Max Thrust Y | 2550 lbf | 11343 N |

| Max Thrust Z | 4200 lbf | 18683 N |

| TOOL CHANGER | S.A.E | METRIC |

|---|---|---|

| Type | Carousel | Carousel |

| Capacity | 20 | 20 |

| Max Tool Diameter (full) | 3.5 in | 89 mm |

| Max Tool Weight | 12 lb | 5.4 kg |

| Tool-to-Tool (avg) | 4.2 s | 4.2 s |

| Chip-to-Chip (avg) | 4.5 s | 4.5 s |

| GENERAL | S.A.E | METRIC |

|---|---|---|

| Coolant Capacity | 55 gal | 208 L |

| AIR REQUIREMENTS | S.A.E | METRIC |

|---|---|---|

| Air Required | 4 scfm @ 100 psi | 113 L/min @ 6.9 bar |

| Inline Air Hose | 3/8 in | 3/8 in |

| Coupler (Air) | 3/8 in | 3/8 in |

| Air Pressure Min | 80 psi | 5.5 bar |

| DIMENSIONS - SHIPPING | S.A.E | METRIC |

|---|---|---|

| Domestic Pallet | 101 in x 99 in x 101 in | 257 cm x 251 cm x 257 cm |

| Export Pallet | 98 in x 92 in x 100 in | 249 cm x 232 cm x 254 cm |

| Weight | 7800 lb | 3539.0 kg |

| ELECTRICAL SPECIFICATION | S.A.E | METRIC |

|---|---|---|

| Spindle Speed | 8100 rpm | 8100 rpm |

| Drive System | Inline Direct-Drive | Inline Direct-Drive |

| Spindle Power | 30.0 hp | 22.4 kW |

| Input AC Voltage (3 Phase) - Low | 220 VAC | 220 VAC |

| Full Load Amps (3 Phase) - Low | 70 A | 70 A |

| Input AC Voltage (3 Phase) - High* | 440 VAC | 440 VAC |

| Full Load Amps (3 Phase) - High* | 35 A | 35 A |

Note: This optional high-voltage internal transformer is not field installable; it must be ordered with the machine.

| HAAS PRODUCT | ROTARY FIT TYPE | FIT REQUIREMENTS |

|---|---|---|

| HA2TS | ALTERNATIVE FIT: CAUTION | When a HA2TS rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| HA5C | ALTERNATIVE FIT: CAUTION | When a HA5C rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| HA5C2 | ALTERNATIVE FIT: CAUTION | When a HA5C2 rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| HA5C3 | ALTERNATIVE FIT: CAUTION | When a HA5C3 rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| HA5C4 | ALTERNATIVE FIT: CAUTION | When a HA5C4 rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| HA5CS | ALTERNATIVE FIT: CAUTION | When a HA5CS rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| HRC160 | POSITIVE FIT | This HRC160 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRC210 | POSITIVE FIT | This HRC210 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRT160 | POSITIVE FIT | This HRT160 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRT160-2 | ALTERNATIVE FIT: CAUTION | When a HRT160-2 rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| HRT160SP | POSITIVE FIT | This HRT160SP Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRT160SS | POSITIVE FIT | This HRT160SS Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRT210 | POSITIVE FIT | This HRT210 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRT210-2 | ALTERNATIVE FIT: CAUTION | When a HRT210-2 rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| HRT210SP | POSITIVE FIT | This HRT210SP Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRTA5 | POSITIVE FIT | This HRTA5 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRTA6 | POSITIVE FIT | This HRTA6 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| T5C | POSITIVE FIT | This T5C Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| T5C2 | POSITIVE FIT | This T5C2 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| T5C3 | POSITIVE FIT | This T5C3 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| TR160 | ALTERNATIVE FIT: CAUTION | When a TR160 rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| TR160-2 | ALTERNATIVE FIT: CAUTION | When a TR160-2 rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| TR200Y | ALTERNATIVE FIT: CAUTION | When a TR200Y rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| TRT100 | POSITIVE FIT | This TRT100 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| TRT160 | POSITIVE FIT | This TRT160 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| TRT70 | ALTERNATIVE FIT: CAUTION | When a TRT70 rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |

| HRT210HT | POSITIVE FIT | This HRT210HT Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRT100 | POSITIVE FIT | This HRT100 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| TH240 | POSITIVE FIT | This TH240 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HRT210SS | POSITIVE FIT | This HRT210SS Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| TRT210 | POSITIVE FIT | This TRT210 Rotary fits with a traditional setup that is most often used on Haas milling machines. |

| HA5C-T | ALTERNATIVE FIT: CAUTION | When a HA5C-T rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. |